ATEX & Anti-Corrosive

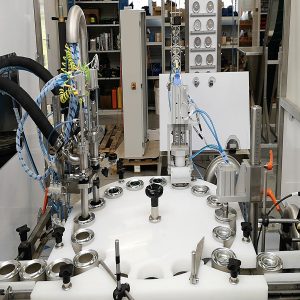

Filling machines for explosive environments (ATEX, Apollo EX-PROOF)

These machines are designed for filling flammable and explosive substances, such as diluents, paints solvents, substances based on acetone, alcohol etc.

The machines are equipped with certified components designed for the use in explosive environments (sensors, motors, pneumatic components, used material etc.)

Part of the delivery is the complete documentation including calculations, certificates for individual elements and risk analysis.