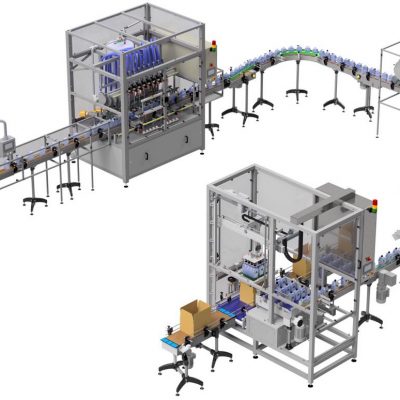

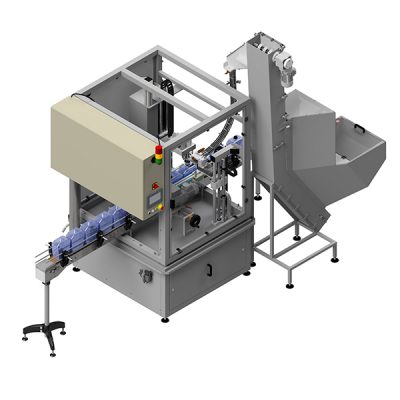

linear Filling & Capper

TECHNOSYSTEM packaging technology Linear Filling & Capping :

- Robust construction

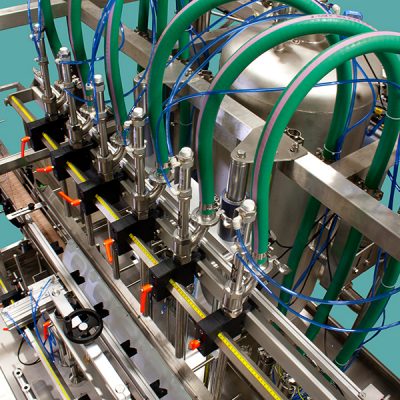

- High filling precision

- Optimal price-performance ratio

- Quick conversion for other sizes without needing spare parts or tools

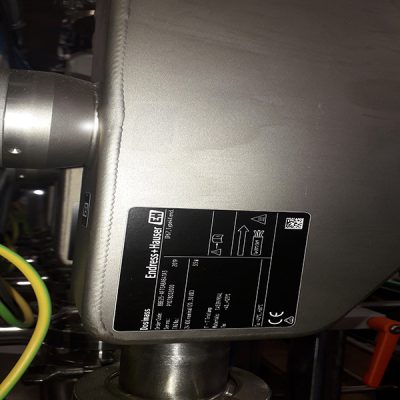

- Use of top components (SMC pneumatics, Siemens control and display systems, Endress Hauser flow meters, Minebea-Intec scales)

- Use of construction materials in compliance with the requirements of GMP and FDA.

Apollo FM - Filling machines based on APOLLO FM with MASS and MAG flow meters.

Apollo GP, Apollo LP - Filling machines with rotation pistons

Linear filling machines with gear pumps (Apollo GP) are mainly intended for filling up of oils and chemical products.

Linear filling machines with Lobe pumps (Apollo LP) are intended to fill food products. Machines equipped with Lobe pumps are easily cleanable using a CIP system, and therefore, they comply with high hygienic standards, as are facilities for the production of ketchup and mayonnaises, fruit concentrates without preservatives, in the milk industry etc.